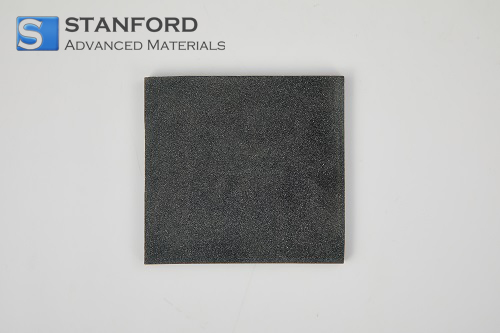

Porous Tantalum Carbide Description

Porous Tantalum Carbide developed by Stanford Advanced Materials (SAM) is a

cutting-edge material engineered to meet the demanding requirements of

next-generation SiC crystal growth systems. With an exceptionally high porosity

of up to 75%, this material offers excellent gas permeability, enabling precise

control of vapor-phase composition, local temperature gradients, and material

flow direction within the thermal field. Unlike conventional graphite or porous

graphite materials that may lead to carbon-related defects or suffer from

insufficient permeability, SAM’s porous tantalum carbide combines superior

hardness, strength, and purity—making it ideal for high-temperature

environments where structural integrity and thermal stability are critical.

Porous Tantalum Carbide Applications

·

Molten Aluminum Transfer

Used for efficiently transferring

molten aluminum from furnaces to molds or other processing units in casting

operations.

·

Non-Ferrous Metal Casting

Ideal for pouring and transferring

various non-ferrous metals such as copper, brass, and zinc alloys.

·

Foundry Operations

Essential in metal foundries for

precise and controlled pouring during metal casting and molding processes.

·

Die Casting and Investment Casting

Employed in die casting and

investment casting processes to handle molten metals with minimal

contamination.

·

Metal Refining and Alloying

Used in refining and alloying

processes where the ladle needs to maintain the integrity of the molten metal.

·

Heat Treatment and Melting Furnaces

Ideal for use in melting and

holding furnaces, ensuring stable metal temperatures during pouring operations.

Porous Tantalum Carbide Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden Box, or Customized.

Kindly review the packaging

details provided for your reference.

Manufacturing Process

1. Testing Method

(1) Chemical Composition Analysis - Verified using techniques

such as GDMS or XRF to ensure compliance with purity requirements.

(2) Mechanical Properties Testing - Includes tensile strength,

yield strength, and elongation tests to assess material performance.

(3) Dimensional Inspection - Measures thickness, width, and

length to ensure adherence to specified tolerances.

(4) Surface Quality Inspection - Checks for defects such as

scratches, cracks, or inclusions through visual and ultrasonic examination.

(5) Hardness Testing - Determines material hardness to confirm

uniformity and mechanical reliability.

Please refer to the SAM testing procedures for detailed information.

Porous Tantalum Carbide FAQs

Q1: What is Porous Tantalum Carbide?

A1: Porous Tantalum Carbide is a high-strength,

high-temperature-resistant ceramic material featuring a controlled pore

structure, designed for use in advanced thermal and crystal growth

applications.

Q2: What is the typical porosity of this material?

A2: SAM’s porous tantalum carbide can achieve porosity levels up to 75%,

with 70% being a standard offering, enabling excellent gas permeability.

Q3: What are the key advantages over traditional porous

graphite?

A3: It offers superior hardness, mechanical strength, purity, and

structural integrity, while avoiding issues like particle shedding, low etch

resistance, and limited gas permeability.

Q4: In what applications is Porous Tantalum Carbide

commonly used?

A4: It is primarily used in SiC crystal growth systems, vapor-phase

composition control, thermal gradient regulation, and gas flow guidance in

high-temperature processes.

Performance Comparison Table with Competitive Products

|

Property / Material

|

Tantalum Carbide (TaC)

|

Silicon Carbide (SiC)

|

Graphite Foam

|

|

Melting Point (°C)

|

~3880℃

|

~2730℃

|

~3600℃

|

|

Thermal Conductivity

|

Moderate (~22 W/m·K)

|

High (~120-200 W/m·K)

|

Moderate to Low (~30-70 W/m·K)

|

|

Electrical Conductivity

|

Good (Conductive)

|

Semi-conductive / Insulating (depends on type)

|

Good (Conductive)

|

|

Hardness (Vickers)

|

Very High (~2000 HV)

|

Very High (~2500-3000 HV)

|

Low (structure is soft and porous)

|

|

Corrosion Resistance

|

Excellent (especially chemical resistance)

|

Excellent (especially in harsh environments)

|

Fair to Moderate (oxidizes at high temps)

|

|

Gas Permeability

|

Tunable (in porous form)

|

Very low in dense form

|

High (very permeable)

|

|

Mechanical Strength

|

High (even in porous form)

|

Very high in dense form

|

Low to moderate (brittle structure)

|