Enameled Copper Wire Description

Enameled Copper Wire is designed to deliver exceptional performance in

demanding electrical applications. Featuring excellent bending properties and

high flexibility of the enamel, this wire ensures smooth and reliable operation

in tight spaces and high-stress environments. It offers outstanding resistance

to abrasion, making it ideal for long-term use in challenging conditions. With

high mechanical strength and superior thermal properties, Enameled Copper

Wire is well-suited for applications subjected to constant high

temperatures and mechanical stress.

In addition to its excellent performance

in extreme environments, it provides excellent resistance to chemicals,

refrigerants, and freon, ensuring durability and reliability. Whether used in

motors, transformers, or other high-performance electronics, Silver Enameled

Wire stands out for its outstanding mechanical and chemical properties, making

it an ideal choice for advanced electrical windings that require both strength

and flexibility.

Enameled Copper Wire Applications

·

Electrical Motors - Winding for electric

motors, both small and large industrial types.

·

Transformers - Winding of transformer coils

for efficient energy conversion.

·

Inductors and Coils - Used in RF circuits and

electromagnetic coils.

·

Speakers and Microphones - Winding for audio

components to improve sound quality.

·

Sensors and Actuators - Manufacturing of

sensors and actuators in automotive and industrial applications.

·

Medical Equipment - Wiring for critical

medical devices, including MRI machines and pacemakers.

·

Aerospace Applications - Wiring for satellites

and aircraft due to its high-temperature resistance.

·

Electrical Appliances - Used in wiring for

household and industrial electrical appliances.

·

Automotive Wiring - Wiring for motors,

electrical systems, and harnesses in automotive applications.

Enameled Copper Wire Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden box, Paper barrel, Iron barrel, or

Customized.

Kindly review the packaging

details provided for your reference.

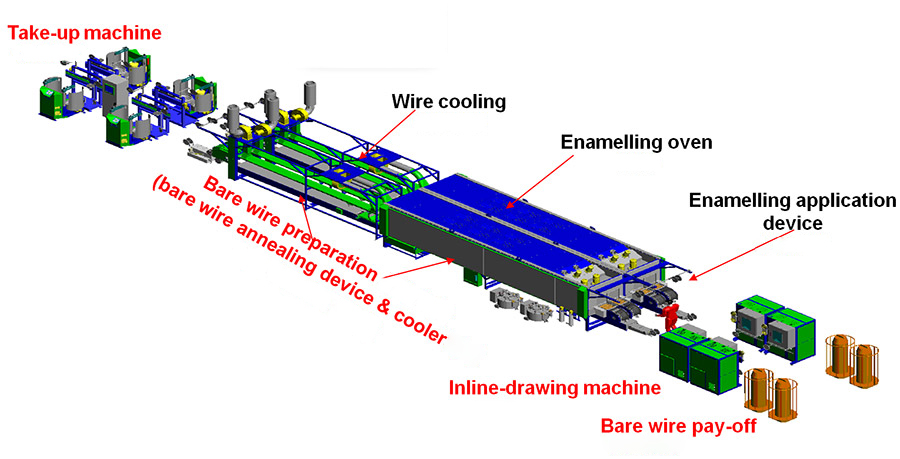

Manufacturing Process

1. Manufacturing Process

2. Testing Method

(1) Direct Reading Spectrometer: Fast and accurate metal

composition analysis.

(2) XRF Spectrometer (X-Ray Fluorescence Spectrometer): Rapid

detection of hazardous substances.

(3) ICP Spectrometer (Inductively Coupled Plasma Spectrometer):

Accurate qualitative and quantitative analysis.

(4) Tensile Strength Tester: Testing material performance.

Please refer to the SAM testing procedures for detailed information.

Enameled Copper Wire FAQs

Q1. What is enameled copper wire?

Answer: Enameled copper wire is copper wire that has been

coated with an insulating enamel layer. The enamel provides electrical

insulation, allowing the wire to be used in various electrical applications

without short circuits.

Q2. What are the key benefits of using enameled copper

wire?

Answer: Enameled copper wire offers excellent electrical

conductivity, flexibility, and resistance to high temperatures. Its thin

insulation allows for tightly wound coils and efficient use of space, making it

ideal for motors, transformers, and other electrical components.

Q3. What are the main applications of enameled copper

wire?

Answer: Enameled copper wire is widely used in motors,

transformers, inductors, solenoids, and other electrical devices that require

tightly wound coils and high-performance electrical conductivity.

Performance Comparison Table with Competitive Products

Enameled Silver Wire vs. Enameled Copper Wire

|

Property

|

Enameled Silver Wire

|

Enameled Copper Wire

|

|

Base Material

|

Silver

|

Copper

|

|

Wire Diameter

|

0.016-0.50 mm, or Customized

|

0.01-0.5 mm, or Customized

|

|

Density (g/cm3)

|

10.49

|

8.93

|

|

Conductivity

|

62.5 S/m*106

|

58.5 S/m*106

|

|

IACS

|

108%

|

101%

|

|

Elongation

|

20%

|

25%

|

|

Tensile Strength

|

200 N/mm2

|

260 N/mm2

|

Related Information

1. Lubricant

We add a small, precise amount of lubricant (mainly a

special type of paraffin) to the wire to achieve excellent winding performance,

preventing wire breakage during various winding processes.

2. Insulation

Types

SAM offers a variety of insulation layers. Polyurethane

insulation has the advantage of being easily soldered and connected, while

polyimide insulation is more heat-resistant. Using composite coatings such as

nylon or polyamide-imide can enhance certain properties, such as mechanical

strength or chemical resistance.