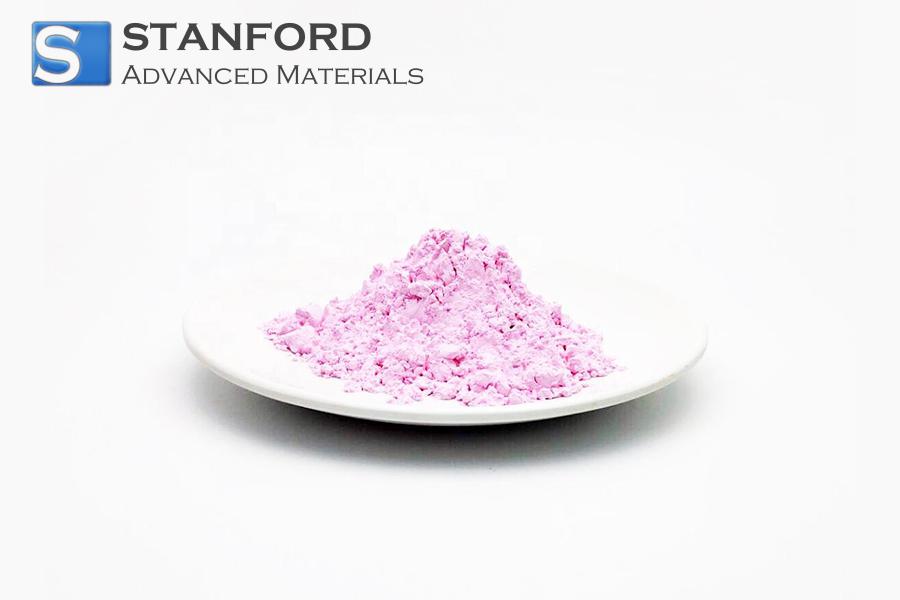

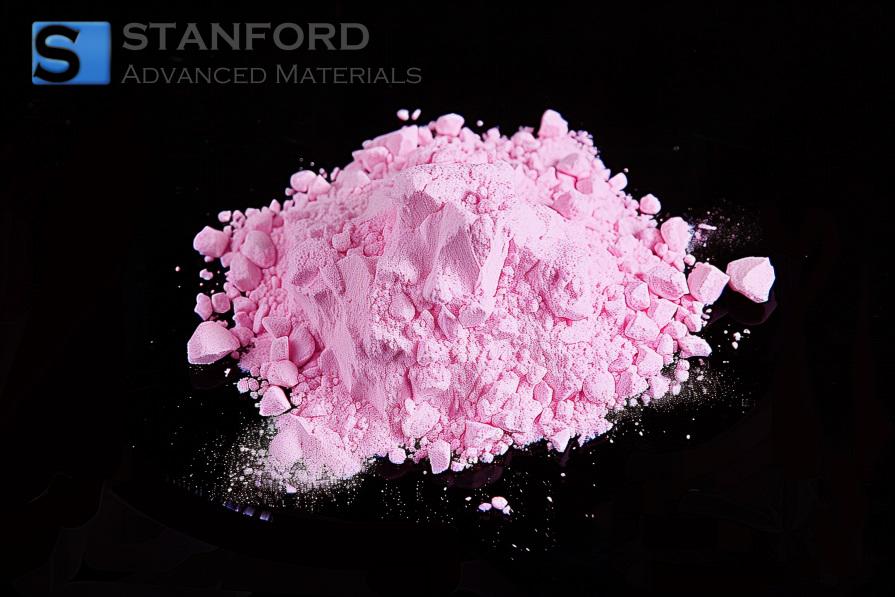

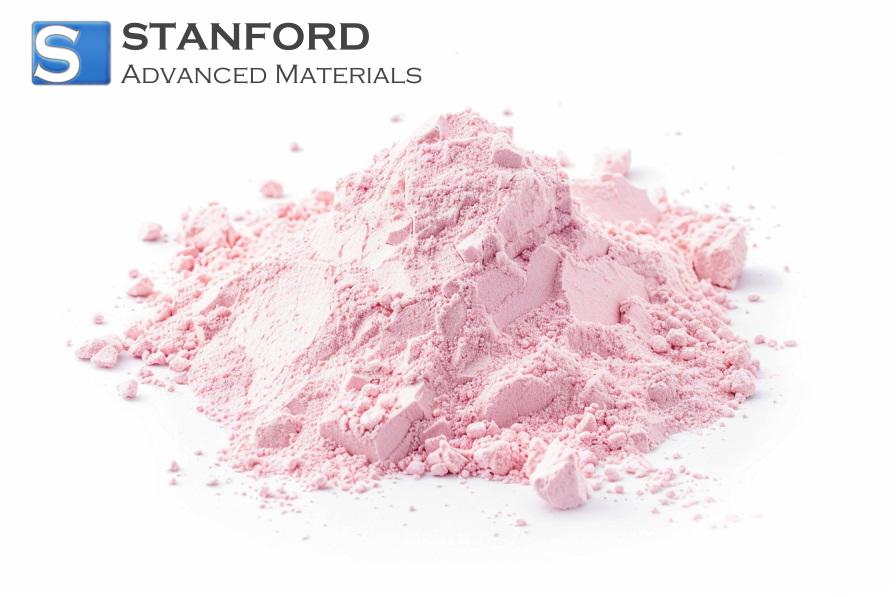

Erbium Carbonate Hydrate Powder Description

Erbium Carbonate Hydrate Powder

(Er₂(CO₃)₃) is a rare-earth inorganic compound characterized by its light pink

to white crystalline appearance and high chemical stability. It is insoluble in

water but readily dissolves in mineral acids (e.g., hydrochloric or nitric

acid), forming erbium ions (Er³⁺) and releasing carbon dioxide. The compound

exhibits thermal decomposition starting around 500°C, breaking down into erbium

oxide (Er₂O₃) and CO₂, a property exploited in synthesizing high-purity erbium oxides

for advanced ceramics or optical materials.

Its hygroscopic nature requires

storage in dry, airtight conditions to prevent moisture absorption and

unintended hydrolysis. With a molecular weight of 497.44 g/mol and a density of

~4.3 g/cm³, it typically exists as a fine powder with particle sizes ranging

from nanoscale to micrometers, depending on synthesis methods (e.g.,

precipitation, hydrothermal routes).

Erbium carbonate demonstrates

moderate reactivity in acidic environments, making it a versatile precursor for

erbium-based compounds. Its luminescent properties—when doped into glass or

crystals—enable applications in fiber optics amplifiers (e.g., Er³⁺-doped

silica fibers for telecommunications) and upconversion phosphors. Additionally,

its low toxicity (compared to other rare-earth compounds) and radiation

stability support niche uses in nuclear shielding materials and

neutron-absorbing ceramics.

Handling requires standard

precautions for rare-earth powders: avoidance of inhalation and contact with

strong oxidizers. Its combination of thermal resilience, controlled reactivity,

and optical utility positions it as a critical material in photonics,

catalysis, and nuclear engineering.

Erbium Carbonate Hydrate Powder Applications

1. Non-Crystalline (Amorphous) Alloys: Indium-alloyed

Cu-based bulk metallic glasses (e.g., Cu₅₄Zr₃₇Ti₈In₁ and Cu₅₀Zr₃₇Ti₈In₅)

exhibit enhanced creep resistance and mechanical stability. These materials are

used in precision instruments and wear-resistant components due to their

homogenous structure and balanced hardness-to-ductility ratio.

2. Semiconductor and Optoelectronic Devices: Indium

compounds like InP/InGaAsP are critical in superluminescent diodes (SLDs) for

fiber-optic gyroscopes. The addition of indium-based electron-blocking layers

improves quantum well efficiency, boosting output power (e.g., from 19 mW to 24

mW) and reliability in high-performance optoelectronic systems.

3. Soldering and Low-Temperature Alloys: Indium-silver

alloys (e.g., In97/Ag3) are widely used in low-temperature soldering (melting

point: 143°C) for heat-sensitive electronics, cryogenic systems, and medical

devices. Their high ductility and thermal stability minimize thermal stress

during bonding.

4. Laser and Advanced Manufacturing: Indium-containing

materials are employed in laser equipment, particularly for components

requiring high thermal and electrical conductivity. For example, indium-coated

substrates enhance laser diode efficiency and longevity.

5. Energy and Environmental Applications: Indium-based

compounds are explored for sustainable technologies, such as recycling gold

from e-waste using graphene-indium hybrids. These materials selectively adsorb

trace gold ions (down to 0.00002 mg/L) with high efficiency (1.85 g/g capacity),

offering eco-friendly resource recovery solutions.

6. Transparent Conductive Oxides (TCOs): Indium tin oxide

(ITO), though not explicitly mentioned in the search results, is a well-known

application of indium in touchscreens, solar cells, and displays. Its high

electrical conductivity and optical transparency remain unmatched in many

optoelectronic applications.

Erbium Carbonate Hydrate Powder Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden Box, or Customized.

Kindly review the packaging

details provided for your reference.

Manufacturing Process

1. Testing Method

(1) Chemical Composition Analysis - Verified using techniques

such as GDMS or XRF to ensure compliance with purity requirements.

(2) Mechanical Properties Testing - Includes tensile strength,

yield strength, and elongation tests to assess material performance.

(3) Dimensional Inspection - Measures thickness, width, and

length to ensure adherence to specified tolerances.

(4) Surface Quality Inspection - Checks for defects such as

scratches, cracks, or inclusions through visual and ultrasonic examination.

(5) Hardness Testing - Determines material hardness to confirm

uniformity and mechanical reliability.

Please refer to the SAM testing procedures for detailed information.

Erbium Carbonate Hydrate Powder FAQs

Q1. What is the appearance and physical state?

It usually appears as a pale pink to rose-colored powder,

insoluble in water but reactive with acids to release CO₂.

Q2. How should it be stored?

Store in a tightly sealed container in a cool, dry place.

Avoid exposure to moisture, acids, and oxidizing agents.

Q3. Is it hazardous?

Erbium carbonate is generally considered low-toxicity, but

dust inhalation or ingestion should be avoided. Standard lab PPE is

recommended.

Related Information

1. Common Preparation Methods

The preparation of praseodymium carbonate powder typically

involves advanced synthetic strategies tailored to achieve desired structural,

morphological, or functional properties. A common method is the coprecipitation

technique, where aqueous solutions of praseodymium salts (e.g., PrCl₃ or

Pr(NO₃)₃) are mixed with a carbonate source such as sodium carbonate (Na₂CO₃)

or ammonium bicarbonate under controlled pH conditions (usually alkaline, pH

9–11). The reaction results in the formation of a pale green precipitate, which

is then filtered, thoroughly washed to remove residual ions, and dried at

moderate temperatures (60–100°C) to yield fine crystalline powder. Parameters

like reaction temperature, stirring rate, and precursor concentration

critically influence particle size and crystallinity.

For applications requiring enhanced surface area or

hierarchical porosity, templating methods are employed. Surfactants such as

sodium dodecyl sulfate (SDS) or block copolymers act as structure-directing

agents, guiding the assembly of praseodymium and carbonate ions into ordered

frameworks. After precipitation, the template is removed via calcination or

solvent extraction, leaving behind materials with tailored pore structures

ideal for catalysis or adsorption.

Another approach involves supported composite synthesis,

where praseodymium carbonate is deposited onto substrates like activated

carbon, silica, or biochar to improve stability and recyclability. For

instance, biochar derived from biomass is impregnated with praseodymium salt

solutions, followed by carbonate precipitation under alkaline conditions. The

composite is then thermally treated to enhance adhesion and activity,

particularly useful in environmental remediation processes.

To produce nanoscale particles with uniform morphology,

solvothermal or hydrothermal methods are utilized. Precursor solutions

containing praseodymium salts and urea (as a precipitant) are sealed in

autoclaves and heated to 120–200°C. The high-pressure, high-temperature

environment promotes controlled crystal growth, yielding nanoparticles with

high purity and narrow size distribution, suitable for specialized applications

like optics or energy storage.

Key characterization techniques include X-ray diffraction

(XRD) for phase analysis, scanning electron microscopy (SEM) for morphological

assessment, and thermogravimetric analysis (TGA) to study decomposition

behavior. Method selection depends on the target application: coprecipitation

offers scalability for industrial production, templating optimizes surface

properties, and solvothermal synthesis prioritizes nanoscale precision.

Adjusting synthesis parameters (e.g., pH, surfactants, thermal profiles)

enables fine-tuning of material performance, ensuring versatility across

diverse technological applications.

Acetylacetonate Hydrate.jpg)