In738LC High Temperature Alloy Powder Description

IN738LC is a nickel-based

superalloy powder strengthened by gamma prime (γ') precipitates (Ni₃(Al, Ti)),

designed for high-temperature applications up to 900°C. Its composition

includes ~16% Cr for oxidation resistance, ~9% Co, 3.7% Al, 3.7% Ti, and trace

refractory elements (Mo, W, Ta, Nb) for solid-solution and grain-boundary

strengthening. The low-carbon design (≤0.13% C) minimizes

carbide formation, enhancing creep resistance and thermal stability.

Key properties include tensile

strength >1,500 MPa and hardness ~40-45 HRC post-aging (450-475°C),

attributed to γ' precipitation and optimized microstructures. It exhibits

exceptional creep resistance under high stress, with minimal creep rates

comparable to cast counterparts after liquid-induced healing (LIH) treatments

in additive manufacturing (AM). The alloy also shows moderate corrosion

resistance, relying on Cr-based passivation, though protective coatings (e.g.,

PtAl) are recommended for harsh environments.

Optimized for laser powder bed

fusion (LPBF), IN738LC achieves >99.9% density with crack-free fabrication,

enabled by controlled solute segregation (Ti/Al). Post-processing includes

solution treatment (1,000-1,050°C) and aging to refine mechanical properties.

Applications span aerospace turbine blades, industrial gas turbine components,

and high-stress AM parts, balancing high-temperature performance with

manufacturability.

In738LC High Temperature Alloy Powder Applications

·

Aerospace Turbine Blades and Engine

Components: IN738LC is extensively used in gas turbine blades and nozzle guide

vanes for aircraft engines, where it withstands temperatures up to 900°C and

cyclic thermal stresses. Its optimized composition (16% Cr, 9% Co) ensures

oxidation resistance and microstructural stability under extreme conditions.

·

Industrial Gas Turbine Hot-Section Parts: The

alloy is employed in industrial gas turbines for components such as combustion

chambers, rotor blades, and seals. Its resistance to hot corrosion (e.g., in

environments with sulfates and chlorides) makes it suitable for power

generation systems exposed to aggressive fuels.

·

Additive Manufacturing (AM) of Complex

Geometries: Optimized for laser powder bed fusion (LPBF), IN738LC powder

enables crack-free fabrication of intricate parts like cooled turbine blades

and lightweight brackets with >99.9% density. Post-processing techniques

like liquid-induced healing (LIH) further enhance its mechanical properties,

achieving creep resistance comparable to cast alloys.

·

High-Stress Components in Energy Systems: The

alloy is used in nuclear reactors and thermal power plants for valve systems,

fasteners, and heat exchangers due to its stability under prolonged

high-temperature service and resistance to stress corrosion cracking.

·

Repair and Refurbishment of High-Value Parts: IN738LC

is applied in wide-gap diffusion brazing to repair turbine blades and other

worn components. This method restores structural integrity while maintaining

high-temperature performance, reducing replacement costs.

·

High-Performance Tooling: Its combination of

wear resistance and thermal stability makes it suitable for injection molds and

extrusion dies in manufacturing processes requiring precision under cyclic

thermal loads.

In738LC High Temperature Alloy Powder Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden Box, or Customized.

Kindly review the packaging

details provided for your reference.

Manufacturing Process

1. Testing Method

(1) Chemical Composition Analysis - Verified using techniques

such as GDMS or XRF to ensure compliance with purity requirements.

(2) Mechanical Properties Testing - Includes tensile strength,

yield strength, and elongation tests to assess material performance.

(3) Dimensional Inspection - Measures thickness, width, and

length to ensure adherence to specified tolerances.

(4) Surface Quality Inspection - Checks for defects such as

scratches, cracks, or inclusions through visual and ultrasonic examination.

(5) Hardness Testing - Determines material hardness to confirm

uniformity and mechanical reliability.

Please refer to the SAM testing procedures for detailed information.

In738LC High Temperature Alloy Powder FAQs

Q1. What are the main properties of In738LC High

Temperature Alloy?

IN738LC is a precipitation-strengthened nickel-based high

temperature alloy with the following notable properties:

High-temperature stability: excellent mechanical properties,

including creep and oxidation resistance, can be maintained at temperatures up

to 850°C.

Thermal corrosion resistance: particularly suitable for high

temperature corrosive environments such as gas turbines and aero-engines.

Microstructure: enhanced high-temperature strength and

ductility through γ′-phase

strengthening, and microcracks can be repaired in additive manufacturing

through post-processing (e.g., LIH technology) to further optimize performance.

Q2. IN738LC Powder Particle Size Requirements and

Selection Recommendations

Particle size distribution: Selected according to 3D

printing technology:

Laser energy source (e.g., SLM): 15-53 μm fine powder to

ensure high precision.

Electron Beam (EBM): 53-105 μm coarse powder to accommodate

higher energy input.

Q3. How is the oxidation resistance of this alloy

enhanced in high temperature environments?

Coating technology: The Reactive Air Aluminizing (RAA)

process is used to form an α-Al₂O₃ layer on the surface, which significantly

reduces the oxidation rate (high-temperature coatings oxidize at a rate up to

100 times lower than low-temperature coatings).

Elemental regulation: Optimize the aluminum content to

promote the formation of protective oxide film and reduce substrate oxidation

damage.

Performance Comparison Table with Competitive Products

Alloy Properties Comparison

|

Property

|

IN738LC

|

IN718

|

Hastelloy X

|

CM247LC

|

|

Max Service Temp

|

850°C

|

700°C

|

1200°C

|

980°C

|

|

Density (g/cm³)

|

7.81

|

8.19

|

8.22

|

8.60

|

|

Tensile Strength

(MPa)

|

|

- Room Temp

(As-printed)

|

1250-1450

|

1276

|

760

|

1150-1350

|

|

- Room Temp

(Post-HTT)

|

1340-1570

|

1450

|

850

|

1400-1600

|

|

- 650°C

|

895

|

1000

|

480

|

950-1100

|

|

Yield Strength

(MPa)

|

|

- Room Temp

(As-printed)

|

850-950

|

1034

|

345

|

900-1050

|

|

- Room Temp (Post-HTT)

|

900-1120

|

1200

|

450

|

1100-1300

|

|

Elongation (%)

|

|

- As-printed

|

23-39

|

12-25

|

35-45

|

5-10

|

|

- Post-HTT

|

9-21

|

15-20

|

20-30

|

3-8

|

|

Creep

Performance

|

|

- 850°C, 365 MPa

|

Rupture Life ≥53 h

|

≥30 h (650°C)

|

≥100 h (815°C)

|

≥100 h (980°C)

|

|

- 982°C, 152 MPa

|

Rupture Life ≥30 h

|

N/A

|

N/A

|

≥50 h (980°C)

|

Related Information

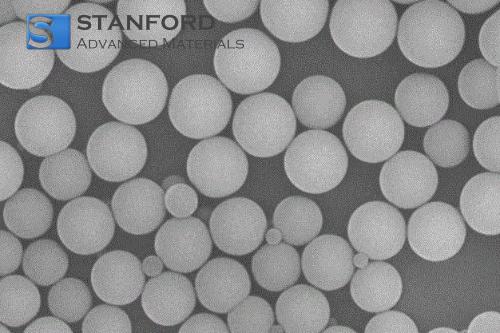

1. Common Preparation Methods

IN738LC high-temperature alloy

powder is primarily produced via gas atomization or plasma rotating electrode

process (PREP). The process typically involves melting pre-alloyed IN738LC

feedstock in an inert atmosphere (e.g., argon), followed by breaking the molten

metal into micron-sized droplets using high-pressure gas jets (gas atomization)

or centrifugal force from a high-speed rotating electrode (PREP). Rapid

solidification ensures the formation of highly spherical particles (>95%

sphericity) with low oxygen content (<200 ppm) and a controlled particle

size distribution (15-150 μm)—finer powders (15-53 μm) for laser-based additive

manufacturing (e.g., SLM) and coarser powders (53-105 μm) for electron beam

melting (EBM). Critical parameters include cooling rates (>10³ K/s) to

suppress elemental segregation, combined with post-processing steps like

screening, airflow classification, and vacuum degassing to optimize powder

flowability (Hall flow rate ≤25 s/50 g) and minimize porosity

(<0.3%). These measures ensure consistency and high-temperature performance

required for advanced additive manufacturing applications.