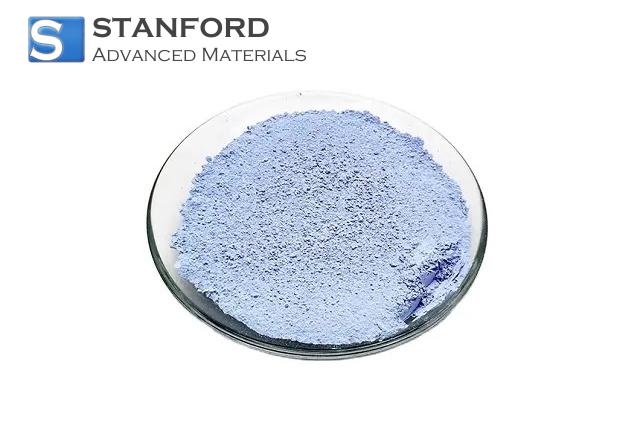

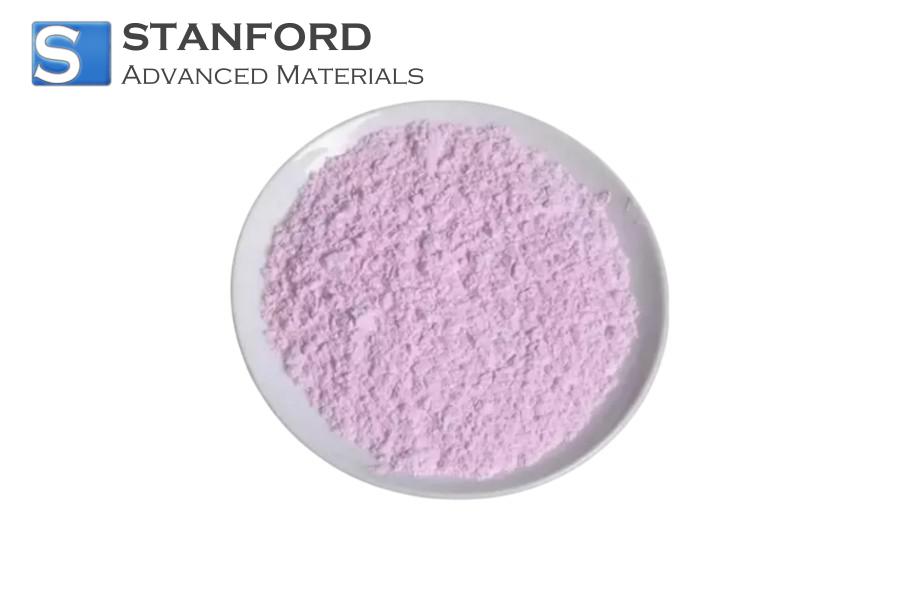

Neodymium Nitride Powder (NdN3) Description

Neodymium Nitride (NdN₃) is an

intriguing compound formed from neodymium and nitrogen, typically appearing as

a dark-colored powder. It belongs to the broader class of rare earth nitrides

and exhibits a unique combination of magnetic, electronic, and structural

properties. The material is known for its semiconducting behavior, arising from

the interaction between the neodymium 4f electrons and nitrogen atoms, which leads

to complex electron localization and conduction mechanisms.

NdN₃ exhibits moderate thermal

stability but is highly sensitive to air and moisture, readily oxidizing or

hydrolyzing when exposed to atmospheric conditions. This reactivity

necessitates storage under inert gas or in vacuum environments. The compound

crystallizes in a cubic or hexagonal lattice, depending on synthesis

conditions, and demonstrates ferromagnetic or antiferromagnetic ordering at low

temperatures due to the presence of unpaired 4f electrons in the Nd³⁺ ions.

Magnetically, NdN₃ shows strong

exchange interactions, which can be tuned through doping or nanostructuring,

making it of interest in spintronic applications and magnetic sensor

development. Additionally, its potential as a high-capacity anode material for

energy storage or as a component in magnetic refrigeration systems is being

explored. These unique attributes make neodymium nitride a valuable subject in

the study of rare-earth-based magnetic and electronic materials.

Neodymium Nitride Powder (NdN3) Applications

1. Magnetic Materials and Spintronics: NdN₃ exhibits

intriguing magnetic properties such as ferromagnetism or antiferromagnetism,

making it a potential candidate for spintronic devices. Its strong 4f electron

interactions allow for use in high-density magnetic storage, magnetic sensors,

and spin valves.

2. Semiconductor and Electronic Devices: As a rare-earth

nitride with semiconducting behavior, NdN₃ is suitable for use in

high-temperature or high-frequency electronics. It is being explored in

next-generation transistors and quantum electronic systems due to its unique

electronic structure.

3. Energy Storage Materials: NdN₃ is studied as a possible

anode material in lithium-ion or sodium-ion batteries. Its theoretical capacity

and structural stability may contribute to enhancing battery performance,

energy density, and cycling life.

4. Magnetocaloric Applications: With promising magnetic

transition properties, NdN₃ may be used in magnetic refrigeration technology,

particularly for low-temperature cooling systems that require efficient and

reversible magnetic entropy change.

5. Hard Coatings and Ceramics: Neodymium nitride can be

utilized in producing ceramic materials or thin films with high hardness, wear

resistance, and thermal stability. It is suitable for extreme environments such

as aerospace, nuclear, or cutting tool applications.

Neodymium Nitride Powder (NdN3) Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden Box, or Customized.

Kindly review the packaging

details provided for your reference.

Manufacturing Process

1. Testing Method

(1) Chemical Composition Analysis - Verified using techniques

such as GDMS or XRF to ensure compliance with purity requirements.

(2) Mechanical Properties Testing - Includes tensile strength,

yield strength, and elongation tests to assess material performance.

(3) Dimensional Inspection - Measures thickness, width, and

length to ensure adherence to specified tolerances.

(4) Surface Quality Inspection - Checks for defects such as

scratches, cracks, or inclusions through visual and ultrasonic examination.

(5) Hardness Testing - Determines material hardness to confirm

uniformity and mechanical reliability.

Please refer to the SAM testing procedures for detailed information.

Neodymium Nitride Powder (NdN3) FAQs

Q1. How is NdN₃ typically used?

NdN₃ is used in magnetic storage, spintronic devices,

battery anode materials, and as part of high-performance ceramics and

electronic components.

Q2. Can NdN₃ be synthesized at a lab scale?

Yes, NdN₃ can be synthesized by reacting neodymium metal

with nitrogen gas at elevated temperatures or via chemical vapor deposition

(CVD) and nitridation processes.

Q3. Is NdN₃ toxic or hazardous?

While neodymium itself is considered moderately toxic, the

nitride form should be handled with care. Proper safety precautions, including

gloves, goggles, and fume hood usage, are recommended.

Performance Comparison Table with Competitive Products

|

Property

|

Neodymium Nitride (NdN₃)

|

Aluminum Nitride (AlN)

|

Silicon Nitride (Si₃N₄)

|

|

Thermal Conductivity

|

Low (≈15-25 W/m·K)

|

High (≈320 W/m·K)

|

Low (≈30 W/m·K)

|

|

Hardness (HV)

|

~16-20 GPa

|

~12 GPa

|

~16 GPa

|

|

Melting Point

|

~2,700-2,900°C

|

2,200°C

|

1,900°C

|

|

Oxidation Resistance

|

Moderate (stable up to 750-900°C)

|

Excellent

|

Good

|

|

Electrical Conductivity

|

Semiconductor/Insulator

|

Insulator

|

Insulator

|

|

Applications

|

High-temperature coatings, magnetic materials, and

optoelectronics

|

Electronics, heat sinks

|

Bearings, cutting tools

|

Related Information

1. Common Preparation Methods

Neodymium nitride (NdN₃) powder is typically synthesized by

reacting high-purity neodymium metal with nitrogen gas at elevated temperatures

in a controlled environment. The neodymium metal is first cleaned and placed in

a high-temperature furnace under an inert atmosphere such as argon. Once the

desired temperature—usually between 800°C and 1200°C—is reached, high-purity

nitrogen gas is introduced into the chamber. The neodymium readily reacts with

nitrogen to form neodymium nitride. After sufficient reaction time, the furnace

is cooled under inert gas flow to prevent oxidation, and the resulting NdN₃

powder is collected. Alternatively, NdN₃ can be produced via chemical vapor

deposition (CVD) or plasma-assisted methods using neodymium-containing

precursors and nitrogen-containing gases, which allow for finer control over

particle size and purity, especially for thin film applications. Regardless of

the method, the powder must be handled and stored in a moisture-free,

oxygen-free environment to maintain its stability and prevent hydrolysis or

oxidation.