30CrNi2SiMoVA Steel Powder Description

30CrNi2SiMoVA Steel Powder is a high-strength low-alloy (HSLA) material engineered for

advanced manufacturing processes, combining exceptional mechanical properties

with precise compositional control. Its chemical composition includes chromium

(Cr), nickel (Ni), molybdenum (Mo), vanadium (V), and silicon (Si), which

synergistically enhance strength, toughness, and thermal stability. Chromium

and molybdenum contribute to improved hardenability and oxidation resistance,

while nickel enhances ductility and fatigue resistance, particularly under

cyclic loading. Vanadium forms fine carbides that refine grain structure,

inhibit grain growth during thermal processing, and improve wear resistance.

The powder typically exhibits ultra-high tensile strength (1800±20 MPa) and

balanced elongation, ensuring structural integrity under extreme stress.

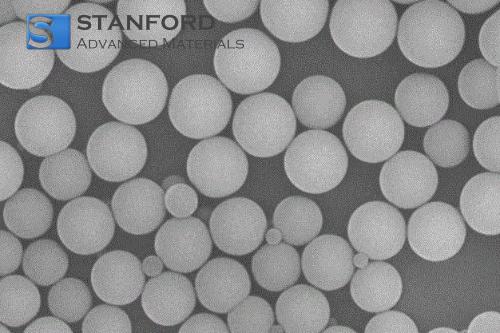

Produced via gas atomization, the

powder features a tightly controlled particle size distribution (15-53 μm),

high sphericity (>95%), and low oxygen content (≤300

ppm), optimizing flowability (Hall flow rate ≤25

s/50 g) and minimizing porosity (<0.3%) in additive manufacturing. Rapid

solidification during atomization suppresses elemental segregation, yielding a

homogeneous microstructure with dispersed carbide precipitates. Post-processing

heat treatments further enhance mechanical properties by promoting martensitic

transformation and carbide stabilization. The powder’s low impurity levels (P,

S ≤0.025%) reduce susceptibility to hot cracking and

embrittlement, ensuring reliability in demanding environments. Its combination

of strength, processability, and microstructural stability makes it a critical

material for high-performance industrial applications requiring precision and

durability.

30CrNi2SiMoVA Steel Powder Applications

·

30CrNi2SiMoVA steel powder is extensively

utilized in industries demanding ultra-high strength, wear resistance, and

thermal stability. In aerospace engineering, it serves as a critical material

for manufacturing turbine blades, landing gear components, and structural

brackets, where its exceptional tensile strength (1800±20 MPa) and fatigue

resistance ensure reliability under extreme mechanical and thermal loads. The

energy sector employs this powder in gas turbine components, nuclear reactor fittings,

and high-pressure valve systems, leveraging its oxidation resistance and creep

performance at elevated temperatures. Within the automotive industry, it is

adopted for producing high-stress parts such as transmission gears,

crankshafts, and suspension systems, benefiting from its refined grain

structure and wear-resistant carbide dispersion.

·

Additive manufacturing (AM) technologies,

including laser powder bed fusion (LPBF) and electron beam melting (EBM),

heavily rely on this powder due to its optimized particle size distribution (15-53

μm) and high sphericity (>95%), which enable precise layer-by-layer

fabrication of complex geometries with minimal porosity. This capability

supports the production of lightweight, topology-optimized designs for industrial

machinery, such as hydraulic actuators and heavy-duty tooling, where both

strength and precision are paramount. Furthermore, its low impurity content (P,

S ≤0.025%) ensures minimal susceptibility to cracking during

post-processing heat treatments, making it suitable for critical defense

applications like armored vehicle components and ballistic protection systems.

The powder’s versatility across these sectors underscores its role in advancing

high-performance, durable engineering solutions.

30CrNi2SiMoVA Steel Powder Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden Box, or Customized.

Kindly review the packaging

details provided for your reference.

Manufacturing Process

1. Testing Method

(1) Chemical Composition Analysis - Verified using techniques

such as GDMS or XRF to ensure compliance with purity requirements.

(2) Mechanical Properties Testing - Includes tensile strength,

yield strength, and elongation tests to assess material performance.

(3) Dimensional Inspection - Measures thickness, width, and

length to ensure adherence to specified tolerances.

(4) Surface Quality Inspection - Checks for defects such as

scratches, cracks, or inclusions through visual and ultrasonic examination.

(5) Hardness Testing - Determines material hardness to confirm

uniformity and mechanical reliability.

Please refer to the SAM testing procedures for detailed information.

30CrNi2SiMoVA Steel Powder FAQs

Q1. Why is low oxygen content critical?

Oxygen levels ≤300

ppm minimize oxide inclusions, reducing brittleness and enhancing fatigue

resistance in high-stress environments.

Q2. What post-processing is required?

Heat treatments (e.g., quenching, tempering) are essential

to achieve optimal martensitic microstructure and carbide stabilization. HIP

(Hot Isostatic Pressing) may reduce residual porosity.

Q3. What industries use this powder?

It is widely adopted in aerospace (turbine blades, landing

gear), energy (gas turbine components), automotive (gears, crankshafts), and

defense (armored systems).

Performance Comparison Table with Competitive Products

Alloy Properties Comparison Table

|

Property

|

30CrNi2SiMoVA

|

IN718

|

IN738LC

|

|

Max Service Temp

(°C)

|

540

|

700

|

850

|

|

Density (g/cm³)

|

7.85

|

8.19

|

8.30

|

|

Tensile Strength

(MPa)

|

|

- As-printed

(Room Temp)

|

1800 ± 20

|

1276

|

1000 ± 50

|

|

- Post-HT (Room

Temp)

|

1800 ± 20

|

1450

|

1000 ± 50

|

|

Yield Strength

(MPa)

|

|

- As-printed

(Room Temp)

|

260 ± 20

|

1034

|

900 ± 50

|

|

- Post-HT (Room

Temp)

|

260 ± 20

|

1200

|

900 ± 50

|

|

Elongation (%)

|

|

- As-printed

|

6 ± 2

|

12-25

|

13 ± 2

|

|

- Post-HT

|

6 ± 2

|

15-20

|

13 ± 2

|

|

Creep

Performance

|

|

- 540°C, 300 MPa

|

Rupture Life ≥50 h

|

N/A

|

N/A

|

|

- 850°C, 365 MPa

|

N/A

|

N/A

|

Rupture Life ≥53 h

|

|

Particle Size

(μm)

|

15-53

|

15-53

|

15-53

|

|

Flowability

(s/50g)

|

≤18

|

≤30

|

≤16

|

|

Oxygen Content

(ppm)

|

≤300

|

≤300

|

≤200

|

Related Information

1. Common Preparation Methods

30CrNi2SiMoVA steel powder is

typically produced using gas atomization, where pre-alloyed feedstock is melted

in an inert argon atmosphere to prevent oxidation. The molten metal is then

disintegrated into fine droplets via high-pressure gas jets, achieving rapid

solidification rates (>10³ K/s) to minimize elemental segregation and ensure

a homogeneous microstructure. This method yields spherical particles (>95%

sphericity) with a controlled particle size distribution (15-53 μm), optimized

for laser-based additive manufacturing systems like SLM or DMLS.

Post-atomization steps include sieving, airflow classification, and vacuum

degassing to refine powder flowability (Hall flow rate ≤18

s/50g) and reduce oxygen content (≤300 ppm). Critical

parameters such as melt temperature, gas pressure, and cooling rate are tightly

regulated to enhance mechanical properties, including ultra-high tensile

strength (1800±20 MPa) and resistance to thermal cracking. The resulting powder

exhibits low porosity (<0.3%) and uniform carbide dispersion, ensuring

reliability in high-stress applications such as aerospace and automotive

components.