40CrNi3SiMoVA Steel Powder Description

40CrNi3SiMoVA steel powder is a high-strength low-alloy (HSLA) material designed for

advanced manufacturing processes, characterized by its exceptional mechanical

performance and optimized microstructure. The alloy’s composition includes

chromium (Cr), nickel (Ni), silicon (Si), molybdenum (Mo), and vanadium (V),

which synergistically enhance strength, toughness, and resistance to hydrogen

embrittlement. Notably, silicon plays a critical role in refining carbide

precipitates during tempering, improving hydrogen trapping efficiency, and

reducing susceptibility to hydrogen-induced cracking.

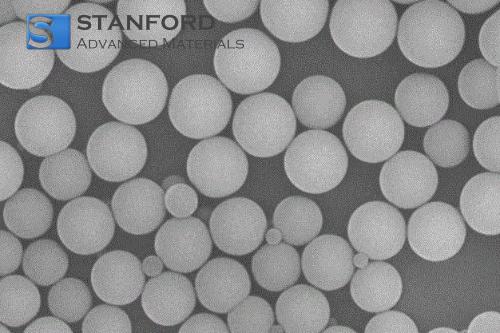

Produced via gas atomization, the

powder exhibits a controlled particle size distribution (15-53 μm) with high

sphericity (>95%) and low oxygen content (<300 ppm), ensuring excellent

flowability (Hall flow rate ≤18 s/50g) and minimal porosity (<0.3%) for

additive manufacturing applications. The rapid solidification process during

atomization suppresses elemental segregation, resulting in a homogeneous

microstructure with dispersed carbides and fine-grained martensitic/bainitic

phases, which contribute to a tensile strength exceeding 1800 MPa and balanced

elongation (6-15%) in both as-printed and heat-treated states.

Vanadium forms stable carbides that

inhibit grain growth and enhance wear resistance, while nickel improves

toughness and fatigue resistance under cyclic loading. The alloy’s low impurity

levels (P, S ≤0.025%) further mitigate brittleness and hot-cracking risks

during post-processing. These properties make 40CrNi3SiMoVA steel powder a

robust candidate for high-stress components in aerospace, energy, and defense

sectors, where reliability under extreme mechanical loads is paramount.

40CrNi3SiMoVA Steel Powder Applications

·

40CrNi3SiMoVA steel powder is widely utilized

in industries requiring ultra-high strength, fatigue resistance, and durability

under extreme mechanical and thermal conditions. In aerospace engineering, it

is employed for manufacturing critical components such as landing gear

assemblies, turbine engine shafts, and structural brackets, where its tensile

strength (exceeding 1800 MPa) and resistance to hydrogen embrittlement ensure

reliability during high-stress operations. The energy sector leverages this

material for gas turbine blades, nuclear reactor pressure vessels, and

high-temperature valve systems, capitalizing on its oxidation resistance and

creep performance at elevated temperatures.

·

In defense and heavy machinery, the powder is

used to produce armored vehicle components, ballistic protection plates, and

mining equipment parts, benefiting from its exceptional wear resistance and

impact toughness derived from vanadium-carbide dispersion. Additive

manufacturing (AM) technologies, particularly laser powder bed fusion (LPBF),

utilize its optimized particle size (15-53 μm) and high sphericity (>95%) to

fabricate lightweight, topology-optimized geometries for industrial tools,

hydraulic actuators, and custom dies with minimal post-processing.

·

Additionally, its low impurity content (P, S ≤0.025%) and resistance to thermal cracking make it suitable

for oil and gas applications, such as drill collars and subsea connectors,

where corrosion resistance and long-term structural integrity are critical. The

alloy’s balanced elongation (6-15%) and fatigue life further enable its use in

automotive racing components, including high-performance crankshafts and

suspension linkages, ensuring durability under cyclic loading. These diverse

applications underscore its role in advancing high-performance engineering

solutions across sectors demanding precision, strength, and reliability.

40CrNi3SiMoVA Steel Powder Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden Box, or Customized.

Kindly review the packaging

details provided for your reference.

Manufacturing Process

1. Testing Method

(1) Chemical Composition Analysis - Verified using techniques

such as GDMS or XRF to ensure compliance with purity requirements.

(2) Mechanical Properties Testing - Includes tensile strength,

yield strength, and elongation tests to assess material performance.

(3) Dimensional Inspection - Measures thickness, width, and

length to ensure adherence to specified tolerances.

(4) Surface Quality Inspection - Checks for defects such as

scratches, cracks, or inclusions through visual and ultrasonic examination.

(5) Hardness Testing - Determines material hardness to confirm

uniformity and mechanical reliability.

Please refer to the SAM testing procedures for detailed information.

40CrNi3SiMoVA Steel Powder FAQs

Q1. What is 40CrNi3SiMoVA steel powder?

40CrNi3SiMoVA is a high-strength low-alloy (HSLA) steel

powder optimized for additive manufacturing (AM). It contains chromium (Cr),

nickel (Ni), silicon (Si), molybdenum (Mo), and vanadium (V) to achieve

ultra-high tensile strength (>1800 MPa), fatigue resistance, and hydrogen

embrittlement resistance.

Q2. What are its limitations?

Limited to moderate-temperature applications (<540°C).

Requires precise AM parameter control to avoid cracking.

Q3. What industries use this powder?

Aerospace: Landing gear, turbine shafts.

Energy: Gas turbine blades, nuclear reactor components.

Defense: Armored vehicles, ballistic plates.

Automotive: High-performance crankshafts, suspension parts.

Oil & Gas: Drill collars, subsea connectors.

Performance Comparison Table with Competitive Products

Alloy Properties Comparison

|

Property

|

40CrNi3SiMoVA

|

IN718

|

CM247LC

|

|

Max Service Temp (°C)

|

540

|

700

|

980

|

|

Density (g/cm³)

|

7.85

|

8.19

|

8.60

|

|

Tensile Strength (MPa)

|

|

- As-printed (Room Temp)

|

1800 ± 20

|

1276

|

1150-1350

|

|

- Post-HT (Room Temp)

|

1800 ± 20

|

1450

|

1400-1600

|

|

Yield Strength (MPa)

|

|

- As-printed (Room Temp)

|

1500 ± 50

|

1034

|

900-1050

|

|

- Post-HT (Room Temp)

|

1600 ± 50

|

1200

|

1100-1300

|

|

Elongation (%)

|

|

- As-printed

|

6-15

|

12-25

|

5-10

|

|

- Post-HT

|

6-15

|

15-20

|

3-8

|

|

Creep Performance

|

|

- 540°C, 300 MPa

|

Rupture Life ≥50 h

|

N/A

|

N/A

|

|

- 850°C, 365 MPa

|

N/A

|

N/A

|

Rupture Life ≥100 h

|

|

Particle Size (μm)

|

15-53

|

15-53

|

53-105

|

|

Flowability (s/50g)

|

≤18

|

≤30

|

≤18

|

|

Oxygen Content (ppm)

|

≤300

|

≤300

|

≤300

|

Related Information

1. Common Preparation Methods

40CrNi3SiMoVA steel powder is

produced via gas atomization, ensuring high purity and controlled particle

morphology. Pre-alloyed feedstock containing chromium, nickel, silicon,

molybdenum, vanadium, and iron is melted in a vacuum induction furnace under an

inert argon atmosphere to prevent oxidation and maintain precise compositional

homogeneity. The molten metal is then forced through a nozzle and fragmented

into fine droplets using high-pressure argon gas jets, achieving rapid cooling

rates (>10³ K/s) to suppress elemental segregation and refine carbide

dispersion. This results in highly spherical particles (>95% sphericity)

with a narrow size distribution (15-53 μm), optimized for laser-based additive

manufacturing. Post-processing steps include sieving to remove outliers (<15

μm or >53 μm), vacuum degassing to reduce oxygen content (≤300 ppm), and

flowability optimization (Hall flow rate ≤18 s/50g) for consistent layer

deposition. Critical parameters such as melt temperature (1600-1650°C), gas

pressure (3-5 MPa), and cooling rate are tightly controlled to ensure

microstructural homogeneity, low porosity (<0.3%), and mechanical properties

exceeding 1800 MPa tensile strength. The process’s scalability and ability to

achieve uniform vanadium carbide dispersion make it ideal for high-stress

aerospace, defense, and energy applications, though plasma rotating electrode

process (PREP) may be used for ultra-low oxygen levels (≤150 ppm) at higher

costs.