12Cr9Ni Die Steel Powder Description

12Cr9Ni is a martensitic stainless

steel powder with 12% chromium (Cr) and 9% nickel (Ni), featuring low carbon

content (≤0.03% C) to enhance toughness and reduce carbides. Alloying

additions like titanium (Ti) and aluminum (Al) enable precipitation hardening,

while molybdenum (Mo) improves thermal stability. After aging (450-475°C), it

achieves tensile strengths over 1,500 MPa and balanced toughness due to its

martensitic matrix with reverted austenite phases, which mitigate brittleness.

Fine precipitates (e.g., Ni3Ti) enhance wear resistance.

The steel maintains mechanical

stability up to 450-500°C and offers moderate corrosion resistance from

chromium, though less than austenitic grades like 316L. Its low carbon content

reduces stress corrosion cracking risks in alkaline environments. Optimized for

laser powder bed fusion (LPBF), the powder ensures crack-free fabrication with

high density (>99.9%) via controlled solute segregation. Post-processing

includes solution treatment (~1,000°C) and aging to maximize strength and

dimensional stability. It outperforms conventional stainless steels in

strength-toughness balance and additive manufacturing compatibility.

12Cr9Ni Die Steel Powder Applications

1. Tooling and Die Manufacturing

Injection Molds: Used for high-precision plastic injection

molds requiring wear resistance and dimensional stability under cyclic thermal

stresses.

Extrusion Dies: Ideal for aluminum or polymer extrusion

tools due to its high-temperature strength (up to 500°C) and resistance to

abrasive wear.

2. Aerospace Components

Turbine Blades and Engine Parts: Suitable for critical

components exposed to elevated temperatures and mechanical loads, leveraging

its thermal stability and fatigue resistance.

High-Stress Fasteners: Used in aircraft assemblies for high

tensile strength (>1,500 MPa) and corrosion resistance.

3. Medical Devices

Surgical Instruments: Biocompatible variants are employed

for scalpels, forceps, and orthopedic tools, benefiting from low cytotoxicity

and sterilization compatibility.

Dental Implants: Processed via additive manufacturing (LPBF)

for custom-shaped implants with high surface finish and structural integrity.

4. Additive Manufacturing (AM)

Complex Geometries: Enables crack-free 3D printing of

intricate molds, lightweight aerospace brackets, and topology-optimized parts

due to optimized solute segregation (Ti/Al) and high-density (>99.9%)

fabrication.

5. Automotive Industry

High-Performance Engine Parts: Used in turbocharger

components and valve systems for its heat resistance and oxidation stability.

Lightweight Tooling: Reduces the weight of stamping dies

while maintaining durability in high-volume production.

6. Energy Sector

Valve Components: Deployed in oil and gas pipelines or

nuclear reactors for corrosion resistance in mildly aggressive environments.

Thermal Power Plant Parts: Withstands cyclic thermal loads

in turbine housings and exhaust systems.

12Cr9Ni Die Steel Powder Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden Box, or Customized.

Kindly review the packaging

details provided for your reference.

Manufacturing Process

1. Testing Method

(1) Chemical Composition Analysis - Verified using techniques

such as GDMS or XRF to ensure compliance with purity requirements.

(2) Mechanical Properties Testing - Includes tensile strength,

yield strength, and elongation tests to assess material performance.

(3) Dimensional Inspection - Measures thickness, width, and

length to ensure adherence to specified tolerances.

(4) Surface Quality Inspection - Checks for defects such as

scratches, cracks, or inclusions through visual and ultrasonic examination.

(5) Hardness Testing - Determines material hardness to confirm

uniformity and mechanical reliability.

Please refer to the SAM testing procedures for detailed information.

12Cr9Ni Die Steel Powder FAQs

Q1. How does it compare to 17-4PH or 316L stainless

steel?

vs. 17- 4PH: Higher toughness and better printability (lower

hot-cracking risk).

vs. 316L: Superior strength and wear resistance but lower

corrosion resistance in harsh environments.

Q2. Is it suitable for corrosive environments?

Offers moderate corrosion resistance (due to Cr content) but

requires coatings for prolonged exposure to acids or chlorides.

Q3. What AM technologies are compatible?

Optimized for laser powder bed fusion (LPBF) due to

controlled solute segregation (Ti/Al) and high packing density.

Performance Comparison Table with Competitive Products

|

Property

|

12Cr9Ni Die Steel

Powder 25

|

17- 4PH Stainless Steel

10

|

316L Stainless Steel 8

|

|

Chemical Composition

|

12% Cr, 9% Ni, ≤0.03%

C, Ti/Al/Mo additions

|

15-17.5% Cr, 3-5% Ni,

3-5% Cu, ≤0.07% C

|

16-18% Cr, 10-14% Ni,

2-3% Mo, ≤0.03% C

|

|

Tensile Strength (MPa)

|

1800 ±50

|

1300-1450

|

485-620

|

|

Yield Strength (MPa)

|

1700 ±50

|

1100-1300

|

170-310

|

|

Elongation (%)

|

6 ±2

|

10-15

|

≥40

|

|

Hardness (HRC)

|

40-45 (after aging)

|

35-45

|

≤95 (HB)

|

|

Max Service Temp. (°C)

|

450-500

|

300

|

870

|

|

Corrosion Resistance

|

Moderate (Cr-based

passivation)

|

Moderate

(acid-resistant)

|

Excellent (Mo-enhanced)

|

|

AM Compatibility

|

>99.9% density

(LPBF, crack-free)

|

Limited (high

hot-cracking risk)

|

Good (common in AM)

|

|

Key Strengths

|

High strength,

AM-friendly, balanced toughness

|

High strength,

cost-effective

|

Superior corrosion

resistance

|

Related Information

1. Common Preparation Methods

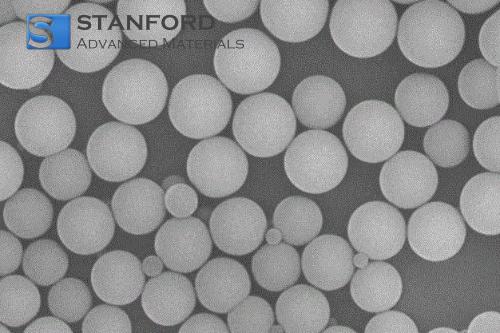

The production of 12Cr9Ni die steel

powder utilizes gas atomization to create spherical particles optimized for

additive manufacturing. In this process, the alloy (composed of 12% Cr, 9% Ni,

≤0.03% C, and trace Ti/Al/Mo) is melted and atomized using high-pressure inert

gas (Ar or N₂), yielding powders with a controlled size range of 15-45 μm,

sphericity >95%, and oxygen content below 100 ppm. These powders are

specifically engineered for laser powder bed fusion (LPBF), requiring optimized

parameters such as laser power (200-350 W), scan speed (800-1,200 mm/s), and

layer thickness (20-40 μm) to achieve crack-free parts with >99.9% density.

Post-processing involves a

two-stage heat treatment: solution treatment at 1,000-1,050°C for 1-2 hours to

homogenize the microstructure, followed by aging at 450-475°C for 4-6 hours to

precipitate hardening phases like Ni₃Ti, resulting in tensile strengths of

~1,800 MPa and hardness of 40-45 HRC. Quality assurance includes rigorous

powder characterization (size distribution via laser diffraction, chemical

analysis by ICP-OES/XRF) and mechanical validation (tensile testing per ASTM

E8, SEM/TEM microstructure analysis). This method ensures scalability, AM

compatibility, and tunable mechanical properties for applications in tooling,

aerospace, and medical devices.