LiCoO2 (LCO) Single-Side Coated Aluminum Foil Description

LiCoO2 (LCO) Single-Side Coated

Aluminum Foil is a key cathode material used in lithium-ion battery research

and development. It consists of a uniform coating of lithium cobalt oxide

(LiCoO2) applied to one side of high-purity aluminum foil. LiCoO2 is a widely

adopted cathode material thanks to its high energy density, stable voltage

profile, and long cycle life. The aluminum foil serves as a lightweight,

conductive current collector that provides mechanical support and excellent

electrical contact.

This coated foil is manufactured by

dispersing LiCoO2 powder, a conductive carbon additive such as Super P, and a

binder like PVDF (polyvinylidene fluoride) in a solvent such as

N-methyl-2-pyrrolidone (NMP) to form a uniform slurry. The slurry is then

coated onto one side of the aluminum foil using techniques like doctor blade or

roll-to-roll coating. After drying and calendaring, the foil exhibits a smooth,

dense electrode layer with strong adhesion and consistent electrochemical

properties.

LiCoO2 single-side coated foil is

ideal for coin cell assembly, lab-scale battery prototyping, and academic

studies focused on electrochemical performance, capacity retention, and

degradation mechanisms. It is commonly used in consumer electronics, wearable

devices, and other applications where energy density and reliability are

critical.

LiCoO2 (LCO) Single-Side Coated Aluminum Foil Applications

1. Lithium-Ion Coin Cell Assembly: Used as a cathode

material in CR2032 and other coin cells for lab-scale testing.

2. Battery Research and Development: Ideal for evaluating

cathode performance, cycle life, and voltage profiles in academic and

industrial R&D.

3. Consumer Electronics Prototyping: Applicable in

developing compact batteries for smartphones, tablets, and laptops.

4. Wearable Devices: Supports small, lightweight battery

designs for fitness trackers, medical sensors, and smartwatches.

5. Reference Electrode Material: Serves as a benchmark for

testing new battery materials in electrochemical studies.

6. Educational and Training Kits: Utilized in university

labs and training programs to demonstrate lithium-ion battery assembly and

behavior.

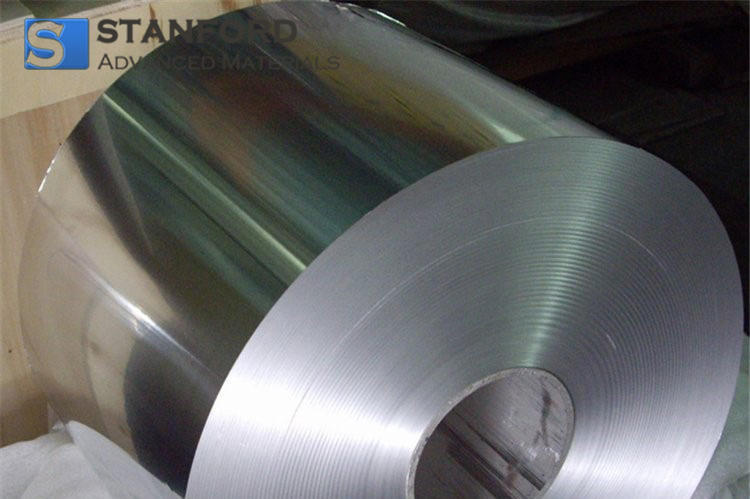

LiCoO2 (LCO) Single-Side Coated Aluminum Foil Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden Box, or Customized.

Kindly review the packaging

details provided for your reference.

Manufacturing Process

1. Testing Method

(1) Chemical Composition Analysis - Verified using techniques

such as GDMS or XRF to ensure compliance with purity requirements.

(2) Mechanical Properties Testing - Includes tensile strength,

yield strength, and elongation tests to assess material performance.

(3) Dimensional Inspection - Measures thickness, width, and

length to ensure adherence to specified tolerances.

(4) Surface Quality Inspection - Checks for defects such as

scratches, cracks, or inclusions through visual and ultrasonic examination.

(5) Hardness Testing - Determines material hardness to confirm

uniformity and mechanical reliability.

Please refer to the SAM testing procedures for detailed information.

LiCoO2 (LCO) Single-Side Coated Aluminum Foil FAQs

Q1. Why is the coating applied to only one side?

Single-side coating allows for simplified battery assembly

and accurate material evaluation in controlled testing environments.

Q2. What is the active material on the foil?

The active material is lithium cobalt oxide (LiCoO₂), known for

its high energy density and stable electrochemical performance.

Q3. What kind of current collector is used?

High-purity aluminum foil is used as the current collector

due to its excellent conductivity and compatibility with LCO.

Related Information

1. Common Preparation Methods

The preparation of LiCoO2 (LCO)

Single-Side Coated Aluminum Foil involves creating a homogeneous slurry by

mixing lithium cobalt oxide (LiCoO2) powder with a conductive carbon additive

such as Super P and a binder like polyvinylidene fluoride (PVDF) in a solvent

such as N-methyl-2-pyrrolidone (NMP). The slurry is thoroughly mixed to ensure

uniform dispersion of the active materials and then applied to one side of

high-purity aluminum foil using a coating technique such as doctor blade or

slot-die coating. After coating, the foil is dried in a vacuum or convection

oven to remove the solvent and promote binder adhesion. It is then calendared

using precision rollers to densify the electrode layer, improve particle

contact, and ensure a consistent thickness across the surface. The final

product is inspected for coating uniformity, adhesion, and mechanical stability

before being cut into required shapes or stored for further use in battery

assembly and testing. This process results in a high-quality, ready-to-use

cathode material suitable for lithium-ion coin cell fabrication, laboratory

research, and electrochemical performance evaluation.