LiMn2O4 Double-Side Coated Aluminum Foil Description

LiMn₂O₄ (LMO) Double-Side Coated

Aluminum Foil is an advanced cathode material designed to enhance the

performance of lithium-ion batteries by coating lithium manganese oxide on both

sides of high-purity aluminum foil. This double-sided configuration

significantly increases the active material loading per unit area, leading to

higher energy density and improved power output compared to single-side coated

electrodes. The spinel crystal structure of LiMn₂O₄ provides excellent lithium-ion

diffusion channels, which support high-rate charge and discharge capabilities

while maintaining thermal stability and safety.

The manufacturing process starts by

preparing a uniform slurry consisting of LiMn₂O₄ powder, conductive additives

like Super P carbon black, and a binder such as polyvinylidene fluoride (PVDF)

dissolved in N-methyl-2-pyrrolidone (NMP). This slurry is coated precisely onto

both sides of aluminum foil using roll-to-roll or slot-die coating techniques.

The coated foil undergoes drying to remove solvent residues, followed by

calendaring to compact the electrode layers, improve mechanical strength, and

ensure consistent thickness and density.

LiMn₂O₄ double-side coated foil is

widely used in lithium-ion coin cells, pouch cells, and cylindrical cells for

research, development, and prototype applications. It is especially suited for

power tools, electric bicycles, and energy storage systems where safety, cycle

life, and rapid charge/discharge are critical requirements.

LiMn2O4 Double-Side Coated Aluminum Foil Applications

1. High-Energy Lithium-Ion Batteries: Used in batteries

requiring increased energy density and compact design for consumer electronics

like smartphones and tablets.

2. Electric Bicycles and Power Tools: Ideal for applications

demanding fast charging, long cycle life, and enhanced safety.

3. Energy Storage Systems (ESS): Suitable for grid storage

and backup power solutions where reliability and cost-efficiency are important.

4. Battery Research and Development: Commonly used in labs

for prototyping, performance testing, and material evaluation.

5. Pouch and Cylindrical Cells: Applied in various cell

formats for experimental and pilot production batteries.

6. Wearable Devices: Supports lightweight and compact

battery designs for smartwatches, fitness trackers, and medical devices.

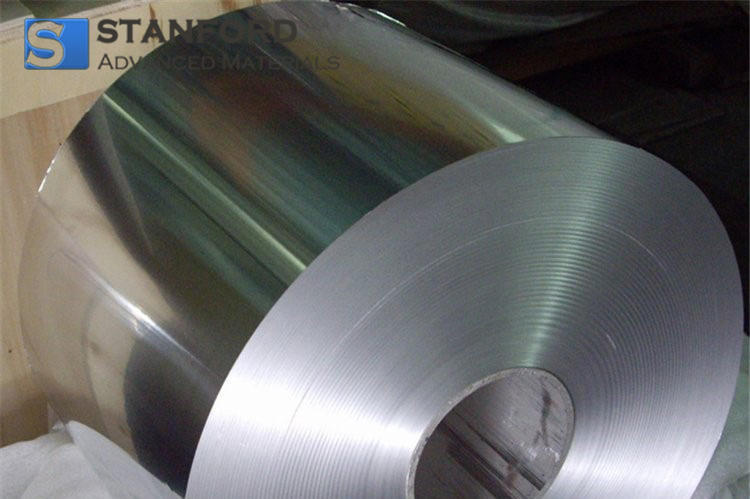

LiMn2O4 Double-Side Coated Aluminum Foil Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden Box, or Customized.

Kindly review the packaging

details provided for your reference.

Manufacturing Process

1. Testing Method

(1) Chemical Composition Analysis - Verified using techniques

such as GDMS or XRF to ensure compliance with purity requirements.

(2) Mechanical Properties Testing - Includes tensile strength,

yield strength, and elongation tests to assess material performance.

(3) Dimensional Inspection - Measures thickness, width, and

length to ensure adherence to specified tolerances.

(4) Surface Quality Inspection - Checks for defects such as

scratches, cracks, or inclusions through visual and ultrasonic examination.

(5) Hardness Testing - Determines material hardness to confirm

uniformity and mechanical reliability.

Please refer to the SAM testing procedures for detailed information.

LiMn2O4 Double-Side Coated Aluminum Foil FAQs

Q1. What are the advantages of double-side coating?

Double-side coating increases active material loading,

enhancing energy density and power output without enlarging battery size.

Q2. What materials are used in the coating?

The coating consists of lithium manganese oxide (LiMn₂O₄),

conductive carbon additives, and binders like PVDF.

Q3. Why is aluminum foil used as the substrate?

Aluminum foil offers excellent electrical conductivity,

lightweight properties, and compatibility with LiMn₂O₄ cathodes.

Related Information

1. Common Preparation Methods

The preparation of LiMn₂O₄ (LMO)

Double-Side Coated Aluminum Foil involves first creating a homogeneous slurry

by mixing lithium manganese oxide (LiMn₂O₄) powder with conductive carbon

additives such as Super P and a binder like polyvinylidene fluoride (PVDF)

dissolved in N-methyl-2-pyrrolidone (NMP) solvent. This slurry is thoroughly

mixed to ensure uniform dispersion and appropriate viscosity. The well-prepared

slurry is then precisely coated onto both sides of high-purity aluminum foil

using advanced coating methods such as roll-to-roll or slot-die coating. After

coating, the foil is dried under controlled temperature and humidity conditions

to remove solvents and enhance binder adhesion. Following drying, the coated

foil undergoes calendaring, where it is compressed by rollers to achieve a

uniform thickness, increase electrode density, and improve mechanical strength.

The final product is then inspected for coating uniformity, adhesion, and

overall quality before being slit or cut into desired sizes for lithium-ion

battery fabrication, testing, and research purposes. This process results in a

high-performance cathode material with enhanced active material loading and

energy density suitable for various advanced battery applications.