LiFePO4 Single-Side Coated Aluminum Foil Description

LiFePO₄ (LFP) Single-Side Coated

Aluminum Foil is a widely used cathode material in lithium-ion battery research

and development, valued for its outstanding thermal stability, safety, and long

cycle life. This material consists of a uniform layer of lithium iron phosphate

coated on one side of a high-purity aluminum foil current collector. The

single-sided design is especially useful for experimental applications,

enabling easier assembly in coin cells and pouch cells, and allowing precise

control over electrode loading and configuration.

The LFP coating offers a stable

discharge voltage around 3.2–3.4 V and excellent cycling performance, making it

suitable for high-safety, moderate-energy-density battery designs. Its robust

olivine crystal structure contributes to superior thermal and chemical

stability, greatly reducing the risk of thermal runaway, which is a key advantage

over other cathode chemistries.

Manufacturing begins with a slurry

made from LFP powder, conductive carbon (e.g., Super P), and a binder such as

PVDF in NMP solvent. This slurry is applied to one side of aluminum foil using

controlled coating methods, then dried and calendared to optimize mechanical

strength and electrode density. The final product is slit or punched into

discs, ready for use in laboratory-scale cells, performance testing, or

early-stage product development.

LiFePO4 Single-Side Coated Aluminum Foil Applications

1. Battery Research & Development: Widely used in labs

for coin cells, pouch cells, and cylindrical cells to test cathode performance

and optimize formulations.

2. Prototype Lithium-Ion Batteries: Suitable for early-stage

product development requiring reliable and consistent cathode behavior.

3. Electric Vehicles (EVs): Applicable in battery designs

that prioritize thermal safety and long cycle life, such as for electric cars,

buses, and scooters.

4. Energy Storage Systems (ESS): Used in stationary

applications like solar energy storage and grid balancing systems, where safety

and longevity are crucial.

5. Backup Power Systems: Ideal for UPS (uninterruptible

power supply) systems requiring stable voltage and long-term reliability.

6. Medical Devices & Industrial Tools: Supports power

solutions where battery stability and safety are critical.

7. Educational and Training Use: Employed in academic

settings to teach lithium-ion battery fabrication and testing.

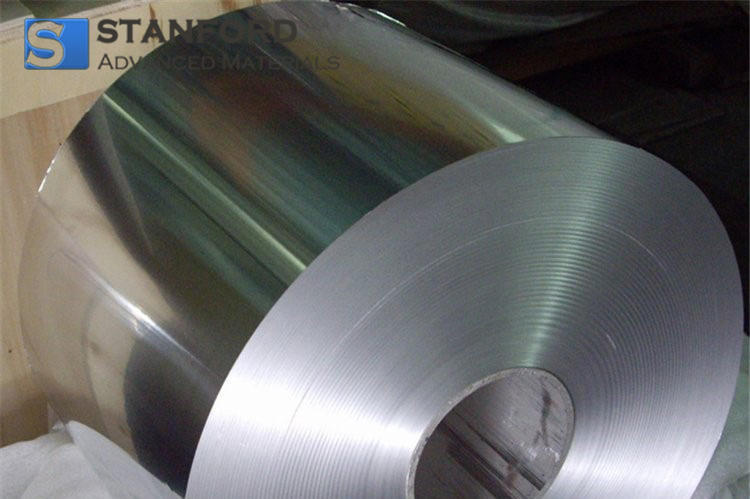

LiFePO4 Single-Side Coated Aluminum Foil Packaging

Our products are packaged in customized cartons of various

sizes based on the material dimensions. Small items are securely packed in PP

boxes, while larger items are placed in custom wooden crates. We ensure strict

adherence to packaging customization and the use of appropriate cushioning

materials to provide optimal protection during transportation.

Packaging: Carton, Wooden Box, or Customized.

Kindly review the packaging

details provided for your reference.

Manufacturing Process

1. Testing Method

(1) Chemical Composition Analysis - Verified using techniques

such as GDMS or XRF to ensure compliance with purity requirements.

(2) Mechanical Properties Testing - Includes tensile strength,

yield strength, and elongation tests to assess material performance.

(3) Dimensional Inspection - Measures thickness, width, and

length to ensure adherence to specified tolerances.

(4) Surface Quality Inspection - Checks for defects such as

scratches, cracks, or inclusions through visual and ultrasonic examination.

(5) Hardness Testing - Determines material hardness to confirm

uniformity and mechanical reliability.

Please refer to the SAM testing procedures for detailed information.

LiFePO4 Single-Side Coated Aluminum Foil FAQs

Q1. What is the main advantage of LiFePO₄ over other

cathode materials?

LiFePO₄ offers excellent thermal stability, non-toxicity,

long cycle life, and strong safety performance compared to materials like NMC

or LCO.

Q2. Why is the foil coated on only one side?

Single-side coating is ideal for laboratory testing, coin

cell assembly, and controlled experiments where precision in material loading

and electrochemical analysis is important.

Q3. What is the role of aluminum foil in this product?

Aluminum foil serves as a lightweight, conductive current

collector that supports the cathode layer and ensures efficient electron

transport.

Related Information

1. Common Preparation Methods

The preparation of LiFePO₄

Single-Side Coated Aluminum Foil involves creating a homogeneous slurry by

mixing lithium iron phosphate (LiFePO₄) powder with conductive carbon (such as Super

P) and a binder like polyvinylidene fluoride (PVDF) in a solvent, typically

N-methyl-2-pyrrolidone (NMP). This slurry is thoroughly mixed to achieve

uniform dispersion and optimal viscosity for coating. The mixture is then

uniformly applied onto one side of high-purity aluminum foil using techniques

such as doctor blade or slot-die coating. After coating, the foil is dried in a

vacuum or convection oven to evaporate the solvent, leaving a solid active

material layer. The dried electrode is then calendared to improve density,

mechanical integrity, and electrochemical performance. Finally, the coated foil

is cut or punched into specific sizes or shapes, such as discs or sheets, for

use in lithium-ion battery assembly and research.